Is solid separation needed to help you manage phosphorus accumulation in soils in your field? Dairy manure tends to have more phosphorus than most cropping systems need when we apply nitrogen-based rates. Over time, this leads to nutrient loading, P Index concerns, and tougher decisions about where to haul your manure.

My last article discussed strategies for tackling this

imbalance, like targeting low-P fields or adopting practices that hold soil in

place. But what if your fields are already saturated, your neighbors aren't

lining up to take solids, and you're still trying to manage more manure than

you have places to put it?

Let's dig into solids separation—not as a silver bullet, but

as a tool that gives you more control over where your nutrients go. We'll focus

on the nuts and bolts of how these systems work, what kind of phosphorus they

capture, and what the real-world tradeoffs look like.

Why Separate?

The basic idea is this: when we separate manure, we split

the nutrients into two different forms:

·

Solids, which are enriched in (especially the

organic and particulate-bound forms)

·

Liquid, which contains most of the ammonium-N

This gives us flexibility. Suddenly, you're not stuck

applying the full nutrient load to every acre. You can:

·

Haul solids to further fields without hauling

water

·

Retain nitrogen-rich liquids for near-barn

applications

Let's look at the tools we've got—and what they do regarding

phosphorus removal and system compatibility.

Tools of the Trade: Separation Systems and Their

P-Capturing Power

Slope Screen or Static Screen

The slope or static screen might be your entry point if

you're looking for the simplest mechanical manure separator. These systems rely

entirely on gravity—no moving parts, no motors, and minimal maintenance.

How It Works

Manure is pumped or flows across an inclined, slotted

screen, usually mounted at a 15–30° angle. As the liquid manure flows over the

screen, coarse solids catch on the surface and slide down while the liquid

passes through into a collection tank or lagoon.

This method works best with thick, undiluted manure and a

relatively high amount of large fiber.

Screw Press

The screw press is one of the most common and accessible

solids separation systems on dairy farms today. It strikes a balance between

simplicity, cost, and performance—making it a solid choice for farms looking to

improve manure handling and pull out some phosphorus without diving into

full-scale treatment systems.

How It Works

At its core, the screw press is a mechanical filter. Manure

is pushed into a cylindrical housing where a rotating auger presses the

material against a screen (often wedge wire or perforated steel). As pressure

builds, the liquid is squeezed out through the screen, and the remaining solids

are discharged at the end of the auger as a damp, fibrous cake.

The design is straightforward, with relatively low energy

and maintenance requirements. No chemicals, no high-speed moving parts, and no

need for complex control systems.

Centrifuge

On the other end of the solids separation spectrum, you've

got the centrifuge—a high-speed, high-cost solution aimed at serious nutrient

recovery. Centrifuges are more common in commercial or tightly regulated

livestock operations, but they're becoming increasingly relevant where

phosphorus management is mission-critical.

How It Works

A centrifuge spins manure at high speeds—often thousands of

revolutions per minute—causing particles to separate by density. Heavier solids

(and the phosphorus they carry) are flung to the outer wall and collected,

while the lighter liquid stays near the center and exits through a different

outlet.

Expected Performance

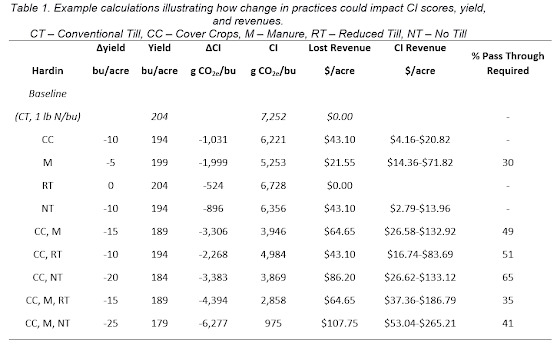

Separation performance was surveyed by Hjorth et al. (2009).

The summarized performance is shown in Table 1. While all separators had the

potential to alter the N:P ratio and create a solid fraction that could move

phosphorus further from the barn, centrifugation had a much higher potential.

Table 1. Separator performance and variation in performance

for solids, total nitrogen, and total phosphorus separation into the solid

fraction.

|

|

Separation Percent |

||

|

|

Dry Matter |

Total N |

Total P |

|

Sloped Screens |

47 (28) |

34 (28) |

30 (22) |

|

Screw Press |

34 (15) |

15 (12) |

13 (7) |

|

Centrifuge |

63 (15) |

36 (14) |

69 (17) |

Table 2. Estimated

characteristics of the separated solids and the remaining liquid after

separation. Centrifugation has the potential to substantially alter the N-to-P ratio

of both the liquid and solid fractions.

|

|

Solids Characteristics (lb/ton) |

Liquid Characteristics (lb/1000 gallons) |

||||||

|

|

Solids |

Total N |

P2O5 |

Available N:P |

Solids |

Total N |

P2O5 |

Available N:P |

|

Sloped Screens |

14 |

8 |

3 |

1.3 |

4 |

16 |

6 |

1.9 |

|

Screw Press |

23 |

8 |

3 |

1.3 |

4 |

18 |

7 |

1.9 |

|

Centrifuge |

33 |

16 |

11 |

0.6 |

2 |

14 |

2 |

4 |

Thinking Ahead: What's Separation For?

Solid separation doesn't eliminate your phosphorus

problem—it reshapes it. It works best when it:

·

It buys you the flexibility to put nutrients

where they're needed

·

Enables cost-effective solids hauling to further

fields or sell to other farmers.

Final Thoughts

Solid separation isn't magic, and it won't make phosphorus

disappear. What it can do is give you options. It lets you make smarter

nutrient management decisions, especially when your fields are overloaded, or

your P Index is getting tight.

·

Screens and screw presses are relatively

affordable and easy to operate—but don't expect miracles.

·

Centrifuges can remove a lot more phosphorus,

but they come with a big price tag and more management.

·

None of them solve the problem unless you also

solve the logistics of where those solids go.

For most dairy farms, separation makes the most sense when

it's part of a bigger strategy:

·

Matching nutrients to fields that can use them

·

Using agronomic practices to reduce runoff and

improve soil uptake

·

Thinking ahead about storage, labor, and timing

And if you're not ready to invest in new hardware? You can

still manage phosphorus smartly by focusing on P Index risk reduction. Cover

crops, ensuring erosion control, using thoughtful application timing, and

squeezing every bushel of uptake you can out of your crop system.

Solid separation isn't a silver bullet. But it can be a good

wrench in the toolbox—especially when you know what job you're trying to get

done.