The carbon intensity (CI) score of a farm's corn or soybean crop is a metric in evaluating agricultural sustainability. For farmers looking to improve profitability and environmental stewardship, understanding CI scoring—and how manure management influences it—can make a big difference.

In this post, we’ll break down what carbon intensity scoring

is, why it matters, and how manure from various livestock operations (dairy,

solid beef, swine, and poultry) impacts the score. We’ll even crunch some

numbers to show how manure management can enhance a farm’s bottom line by

improving the CI of its crops.

What Is Carbon Intensity Scoring?

Carbon intensity scoring is a way to measure the greenhouse

gas (GHG) emissions associated with producing a specific product, such as corn

or soybeans. The score is expressed as kilograms of CO₂-equivalent per unit of

output—typically per bushel for grain crops.

The GREET model (Greenhouse Gases, Regulated Emissions, and Energy Use in Technologies) developed by Argonne National Laboratory is often used to calculate CI scores. Key components of the calculation include:

- Soil carbon dynamics: Gains or losses in soil organic carbon.

- Nitrous oxide emissions: From soil or fertilizer (manure) application.

- Fertilizer inputs: Both synthetic fertilizers and manure.

- Yield: Higher yields generally dilute the CI score.

- Fuel use: Diesel for tractors and transport; grain drying

Why Does Carbon Intensity Scoring Matter?

Carbon intensity scoring matters because low-CI crops can

open doors to new markets and revenue streams. For example, corn with a low CI

score is highly desirable for ethanol plants aiming to reduce their own CI for

carbon credit programs or low-carbon fuel standards. Similarly, soybeans with

low CI may become more attractive for renewable diesel production or

sustainable supply chains.

For farmers, this means practices that lower CI scores—such

as manure use—could add value to their crops.

For livestock producers, low-carbon-intensity (CI) crops

like corn significantly contribute to reducing the carbon intensity of animal

production. In some cases, the low carbon intensity feeds may be fed to the

animal. In others, the grown grain may go to an ethanol plant. Ethanol plants

using low-CI corn not only create low-CI ethanol but also generate distillers’

grains with a lower CI. These distillers’ grains are widely used as livestock

feed, creating a direct link between crop CI and the carbon footprint of the animals

consuming them. This connection is especially important for farms pursuing

carbon-neutral livestock systems, where every component—from feed to manure

management—impacts the overall emissions profile. By integrating low-CI feed

into their operations, livestock producers can reduce their greenhouse gas

emissions and enhance their position in sustainable agricultural markets.

Manure’s Role in Carbon Intensity Scoring

Manure offers multiple pathways to reduce the carbon

intensity of crop production:

·

Replacing Synthetic Fertilizers: Manure provides

nitrogen, phosphorus, and potassium, reducing the need for synthetic

fertilizers, whose production is energy-intensive and GHG-heavy.

·

Enhancing Soil Carbon Storage: Organic matter in

manure improves soil structure and boosts soil organic carbon levels, which can

lower CI scores by sequestering carbon.

·

Reducing Nitrous Oxide Emissions: Unlike

synthetic fertilizers, certain manures release nitrogen more slowly,

potentially reducing nitrous oxide emissions from soil.

Comparing Manures: The Math Behind the Benefits and

potential economic benefits

The

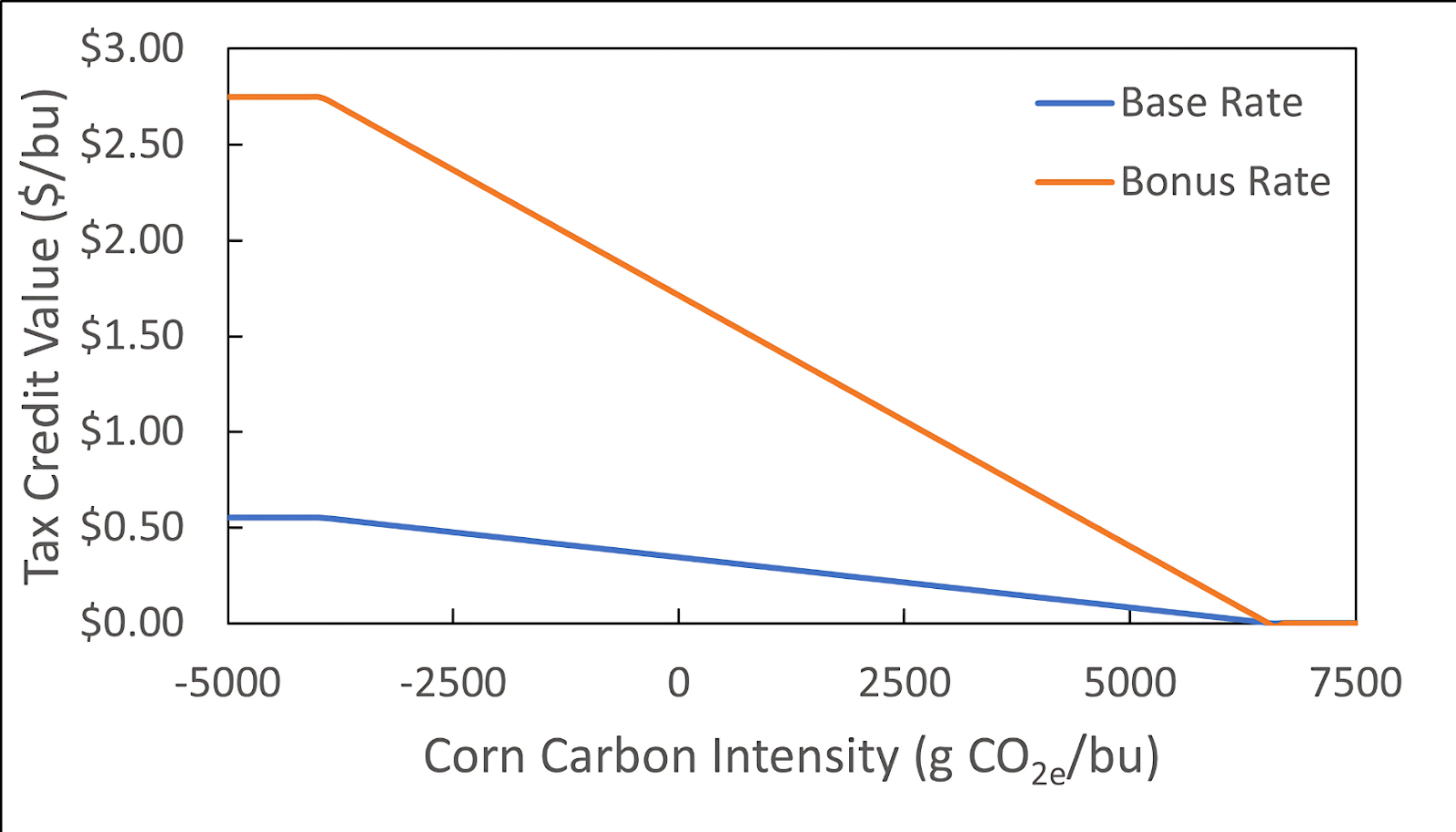

45Z tax credit, part of the Inflation Reduction Act, is available to biofuel

refineries producing low-carbon fuel from 2024 to 2027. This credit benefits

facilities that produce fuel with emissions below 50 kg of CO₂

per million BTU. Specifically, this tax credit offers $0.20 × [1 – (kg of CO2e

per mmBTU / 50)] per gallon produced; if certain wage and apprenticeship

requirements are met the credit could go from $0.20 to $1.00. At this time, the

tax credit is provided to the fuel refiner. As such, farmers may earn a premium

for low-CI corn or soybeans if biofuel producers pursue these credits and use

the CI score of the grain processed to qualify, with the percent of funds

passing through to the farmer unknown at this time. Figure 1 provides an

illustration of potential value per bushel of corn for both credit rates

assuming 100% pass through.

Lowering CI often aligns with cost-effective and sustainable

practices. Here are steps to consider:

- Fuel Efficiency: Optimize equipment and field passes

to reduce fuel use.

- Nutrient Management: Match nutrient applications to crop

needs, minimizing nitrous oxide emissions, and use sources of “green”

nitrogen.

- Cover Crops: Capture carbon in the soil, reduce

erosion, and boost soil health.

- Reduced Tillage: Minimizing soil disturbance can

enhance soil carbon storage.

- Stover Harvest: Provides biofuel feedstock but must be

balanced with soil health.

- Manure Use: Manure adds nutrients, builds soil health,

and increases soil carbon.

These practices can improve your CI score, sustainability, and

eligibility for incentives that reward low-emissions.

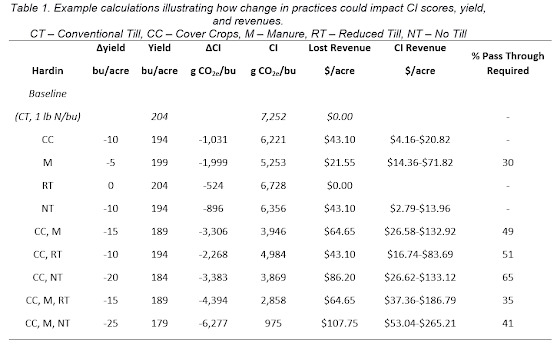

To help illustrate potential impacts on revenues, we estimated

what may occur in certain situations.

Table 1. Example

calculations illustrating how change in practices could impact CI scores,

yield, and revenues.

CT – Conventional Till, CC

– Cover Crops, M – Manure, RT – Reduced Till, NT – No Till

Incorporating manure into your fertility program not only

reduces input costs but also improves the value of your crops in low-CI

markets. For instance:

Corn sold to ethanol plants offering premiums for low-CI

grain may yield higher profits.

Soybeans with improved CI may gain competitive advantages in

renewable diesel supply chains.

To fully capitalize on manure’s CI-reducing potential, it’s

important to sample and analyze the manure, apply it at agronomically optimal

rates, and integrate cover crops or conservation tillage to maximize soil

carbon gains.

If you are looking to get an idea of what the CI score of

corn may be for your field, this calculator

does a great job of getting you close.

Final Thoughts

Manure management is an opportunity to add value to your

farm. By reducing synthetic fertilizer use, improving soil health, and lowering

carbon intensity scores, manure can help farmers unlock new revenue streams

while improving sustainability.